Railing Framework

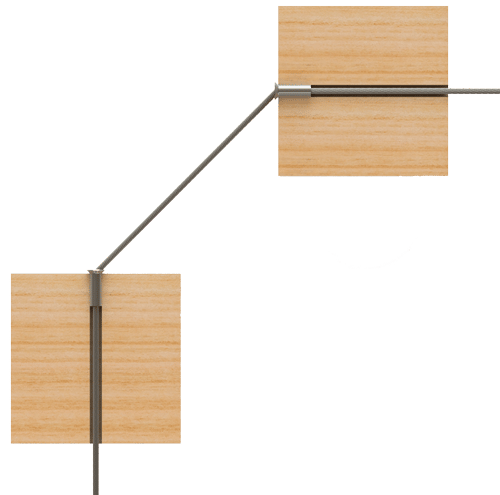

RAILING FRAMEWORK BASICS - WOOD

All railing projects being with the proper framework. The most common framing materials are wood and metal. To provide the stability and safety to your project, more than 200 pounds of tension is applied to the end posts. Each post must be substantial enough to handle the tension.

ADA ALUMINUM GRAB RAIL (optional)

Can be used as a supplemental grab rail with wood and composite rail systems to meet code requirements (see aluminum illustration below for details).

![Wood-Post-Render5[57] wood railing system](https://www.railfx.net/wp-content/uploads/sites/3/elementor/thumbs/Wood-Post-Render557-scaled-q2w0xubq7gx5ebhr8dyyqw46v72ja5mokavshbq4ow.jpg)

TOP RAIL

Use a strong, rigid top rail that can be fastened to all

posts securely.

END POST

Where cables terminate set end posts

3" - 3½" away from any structure for

easy access to install and tension cables.

CORNER POSTS

A. Must terminate cables and start a new cable run

at every wood single corner post

B. Allows cables to pass directly through Corner

Posts using RailFX Post Protector Tubes.

(See Illustration A and B below for single and

double post options)

INTERMEDIATE POST

Cable passes directly through intermediate

post. Max post spacing is 5'. Post spacing

greater than 5' requires a cable support brace.

CABLE BRACE

Used when cable spans are greater than 5'.

![Wood-Post-Render5[57] wood railing system](https://www.railfx.net/wp-content/uploads/sites/3/elementor/thumbs/Wood-Post-Render557-scaled-q2w0xubq7gx5ebhr8dyyqw46v72ja5mokavshbq4ow.jpg)

TOP RAIL

Use a strong, rigid top rail that can fastened to all posts securely.

END POST

Where cables terminate set end posts 3″ – 3½” away from any structure for easy access to install and tension cables.

CORNER POSTS

A. Single Corner Post

Must terminate cables and start a new cable run at every wood single corner post.

B. Double Corner Post

Allows cables to pass directly through Corner Posts using RailFX Post Protector Tubes.

(See Illustration A and B below for single and double post options)

INTERMEDIATE POST

Cable passes directly through intermediate post. Max post spacing is 5′. Post spacing greater than 5′ requires a cable support brace.

CABLE BRACE

Used when cable spans are greater than 5′.

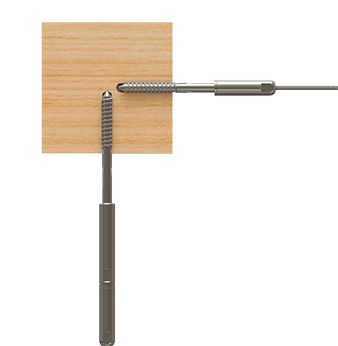

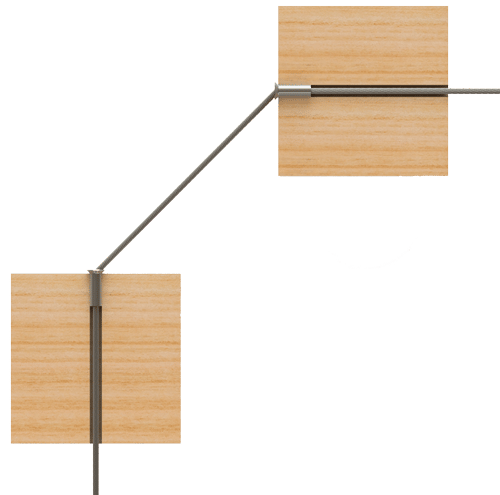

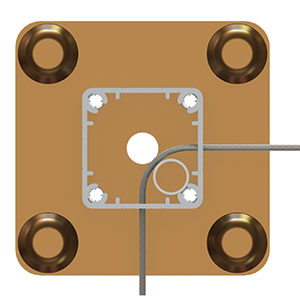

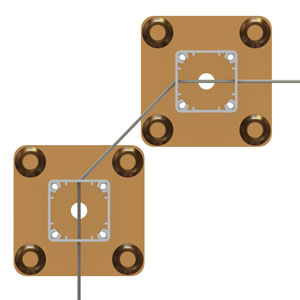

WOOD CORNER POST OPTIONS

A

Single Post Cables

Terminating

B

Double Post using

Post Protector Tubes

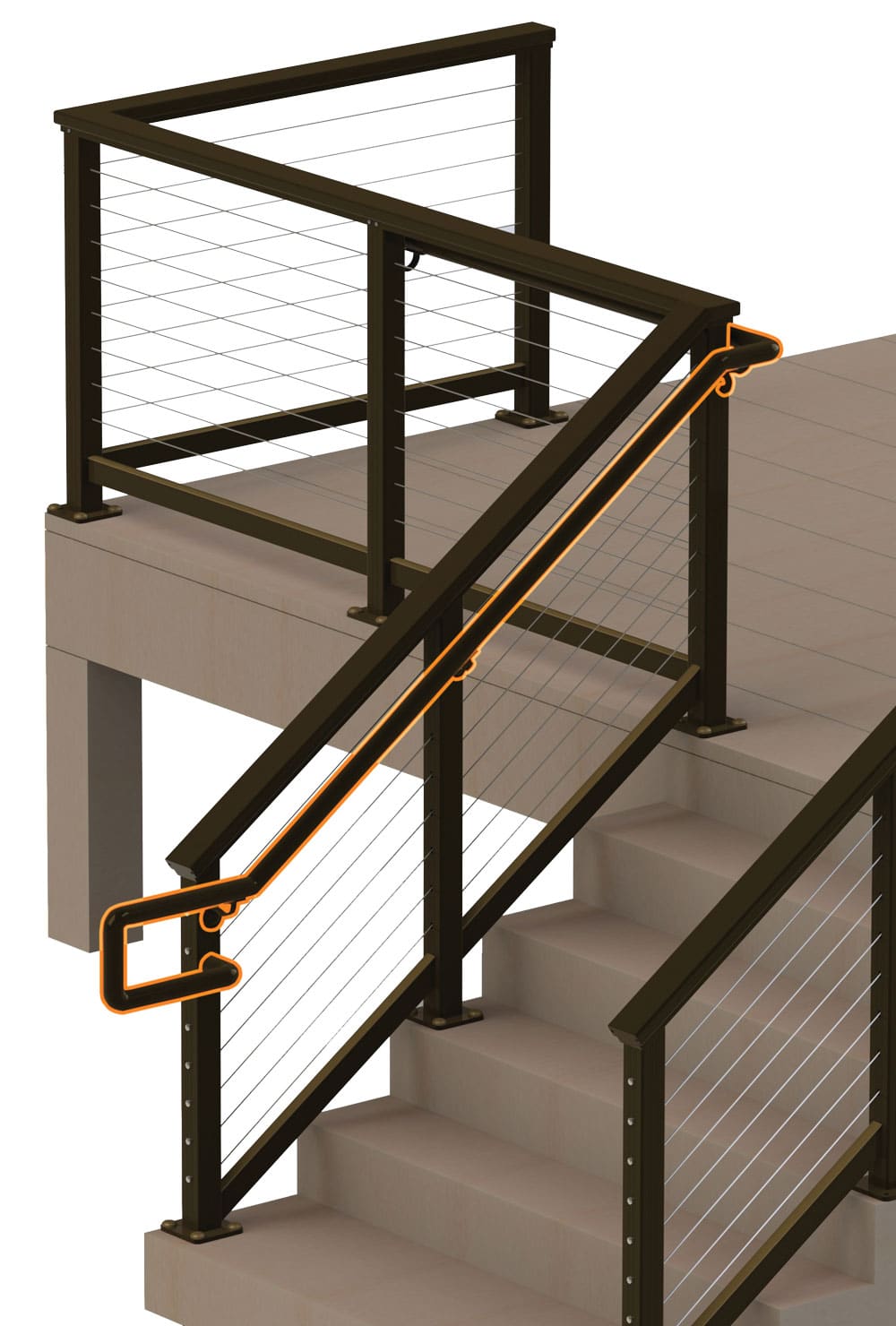

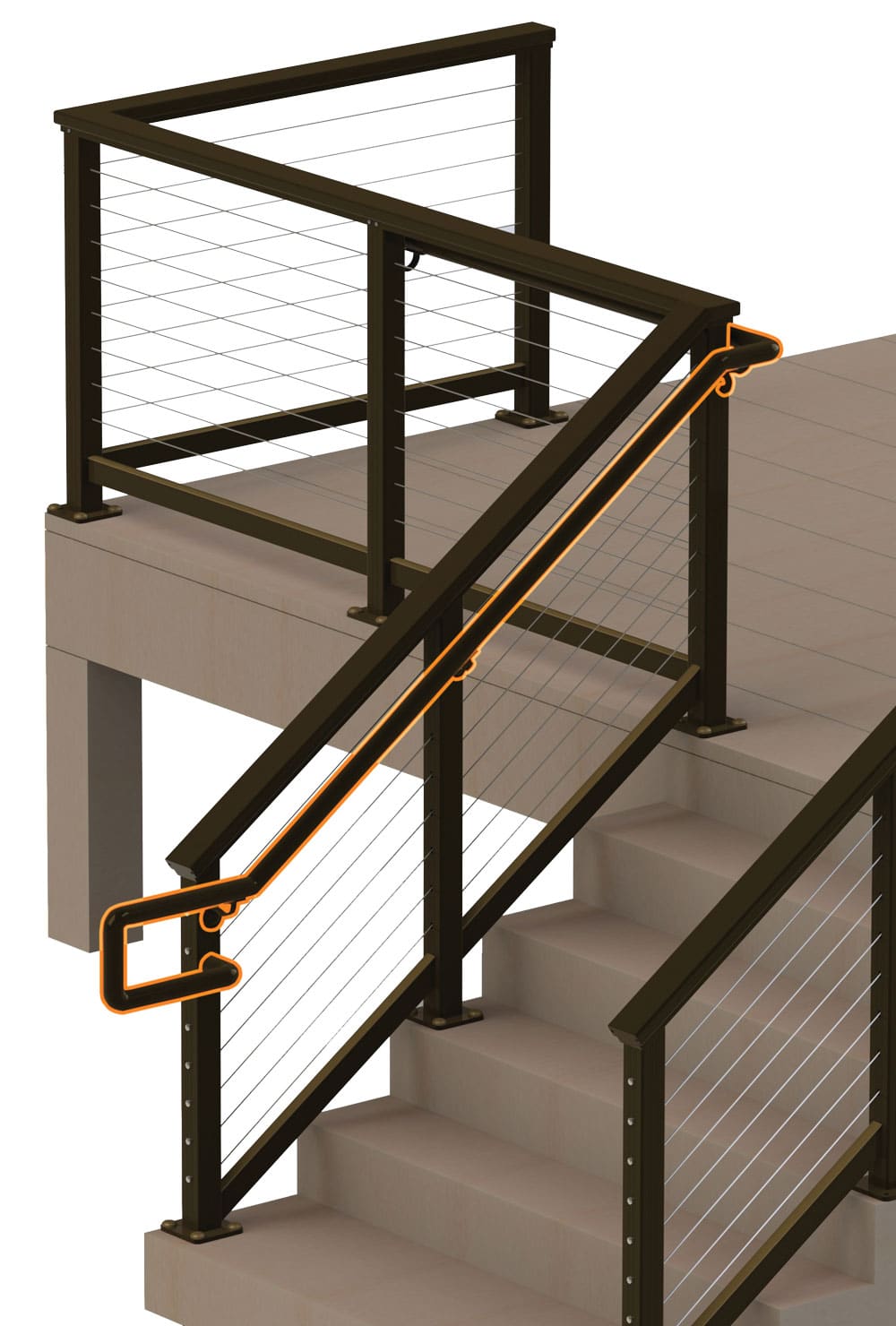

RAILING FRAMEWORK BASICS - ALUMINUM

TOP RAIL

Use a strong, rigid top rail that can fastened to all

posts securely.

END POST

Where cables terminate set end posts

3" - 3½" away from walls for easy access to tension cables.

CORNER POSTS

A. SINGLE CORNER POST

Allows cables to pass continuously through

corner posts.

2. DOUBLE CORNER POST

Allows cables to run continuously through

corner posts.

(See A and B illustrations below for single and

double post options)

INTERMEDIATE POST

Cable passes directly through intermediate

post. Max post spacing is 5'. Post spacing

greater than 5' requires a cable support brace.

BOTTOM RAIL

Bottom Rail is optional. Bottom rail is required

when installing rail that needs to meet handicap

ADA requirements.

ADA HAND RAIL (optional)

Used as a supplemental grab rail when going

downstairs too large to meet code.

TOP RAIL

Use a strong, rigid top rail that can fastened to all posts securely.

END POST

Where cables terminate set end posts 3″ – 3½” away from walls for easy access to tension cables.

CORNER POSTS

A. Single Corner Post

Allows cables to pass continuously through corner posts.

B. Double Corner Post

Allows cables to run continuously through corner posts.

(See Illustration A and B below for single and double post options)

INTERMEDIATE POST

Cable passes directly through intermediate post. Max post spacing is 5′. Post spacing greater than 5′ requires a cable support brace.

BOTTOM RAIL

Bottom Rail is optional. Bottom rail is required when installing rail that needs to meet handicap ADA requirements.

ADA HAND RAIL (optional)

Used as a supplemental grab rail when going downstairs too large to meet code.

ADA HANDRAIL COMPONETS

RailFX offers ADA compliant components that are easy to install, easy to hold on to, and durable.

HANDRAIL

EXTRUSION

HANDRAIL

END CAP

30° 33° 36° HANDRAIL

CONNECTOR

90° HANDRAIL

CONNECTOR RETURN

90° HANDRAIL

CONNECTOR

HANDRAIL

MOUNT

METAL CORNER POST ORIGINS

A

B

CORNER POST FITTINGS OPTIONS

For a continuous cable impression, RailFX fittings are designed to reside within the same post in several configurations when two cable runs intersect at corner posts.

Tensioning: Every cable run needs at least one tensioning cable fitting. A tensioning fitting is attached to either end or corner posts and is used to tension cable tight enough to pass building code requirements.

Non-Tensioning: Non-tensioning fittings are used in conjunction with a tensioning fitting. A non-tensioning fitting is used to attach the cable to a end or corner post.

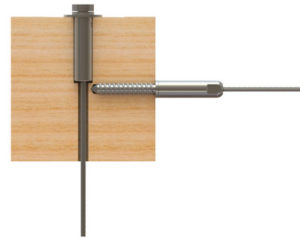

WOOD POST

SINGLE CORNER POST CABLE INSTALLATION OPTION

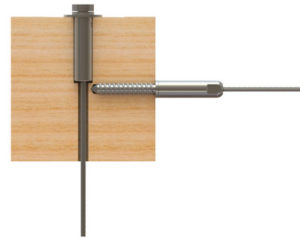

SLEEVED POST

SINGLE CORNER POSTCABLE INSTALLATION OPTION

Basic Cable Kit - FlexFX Non-Tensioner

Professional Cable Kit - FlexFX Non-Tensioner

FlexFX Tensioner

FlexFX Non-Tensioner

WOOD POST

SINGLE CORNER POST CABLE INSTALLATION OPTION

Basic Cable Kit - FlexFX Non-Tensioner

Professional Cable Kit - FlexFX Non-Tensioner

SLEEVED POST

SINGLE CORNER POST CABLE INSTALLATION OPTION

FlexFX Non-Tensioner

FlexFX Tensioner

WOOD POST

DOUBLE CORNER POST CABLE INSTALLATION OPTION

To End Post

Post Protector Tube

Illustrated using Basic Cable Kit

FlexFX Non-Tensioning

FlexFX Tensioning