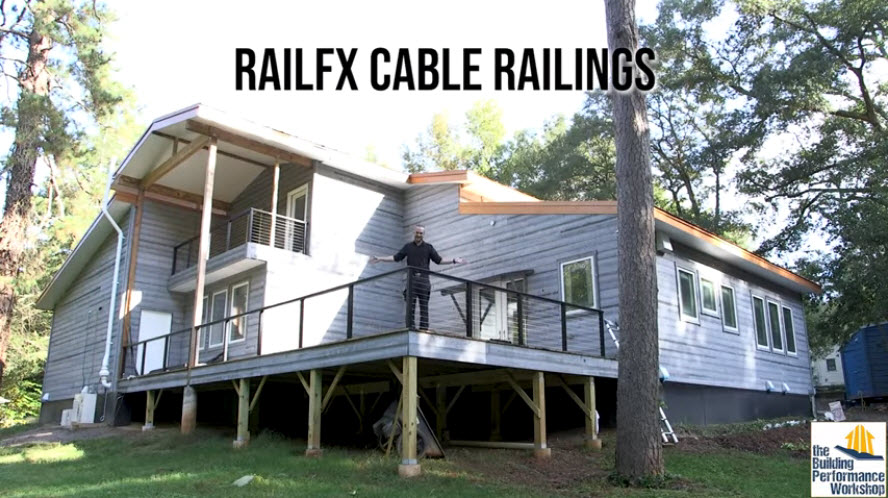

Case Study: Corbett Lunsford on Modern Cable Railing Systems

Project: Atlanta Homestead for Home Diagnosis T.V.

Forever Home Update: Interior Stairway Cable Railing Installation

RailFX update on the Forever Home Case Study from November 25th: Corbett is making the finishing touches to his Atlanta forever home and recently installed RailFX cable railing systems on the interior stairway. Corbett said the real difference for the internal cable run is the amount of use they will experience with three small children running up and down the stairs.

He opted for fascia-mounted posts on the stairway, which was a different attachment process than he experienced on the outside’s surface-mounted posts. Since the interior stairway is four feet wide, code dictated he install ADA compliant railings on each side. Corbett used RailFX’s ADA graspable handrail and RFX 400 top rail option in silver. He used pecan wood from Grace’s family’s backyard for the top rail for an upscale finishing touch. View the RailFX Stair Cable Railing Installation video from Home Diagnosis TV below for more details.