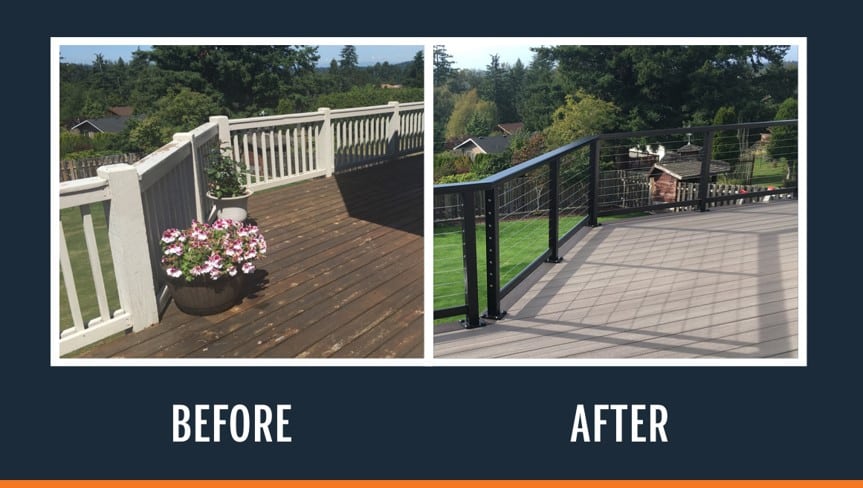

Building a deck is a balance between form and function. Homeowners want a deck that increases their living space and blurs the lines between indoors and outdoors. However, without structural elements like walls, decks require railings to both define the space and, most importantly, keep users safe.

While a deck can be almost any shape, size and height, every deck railing needs to meet standardized building codes. Codes keep people and animals safe, particularly when it comes to elevated decks.

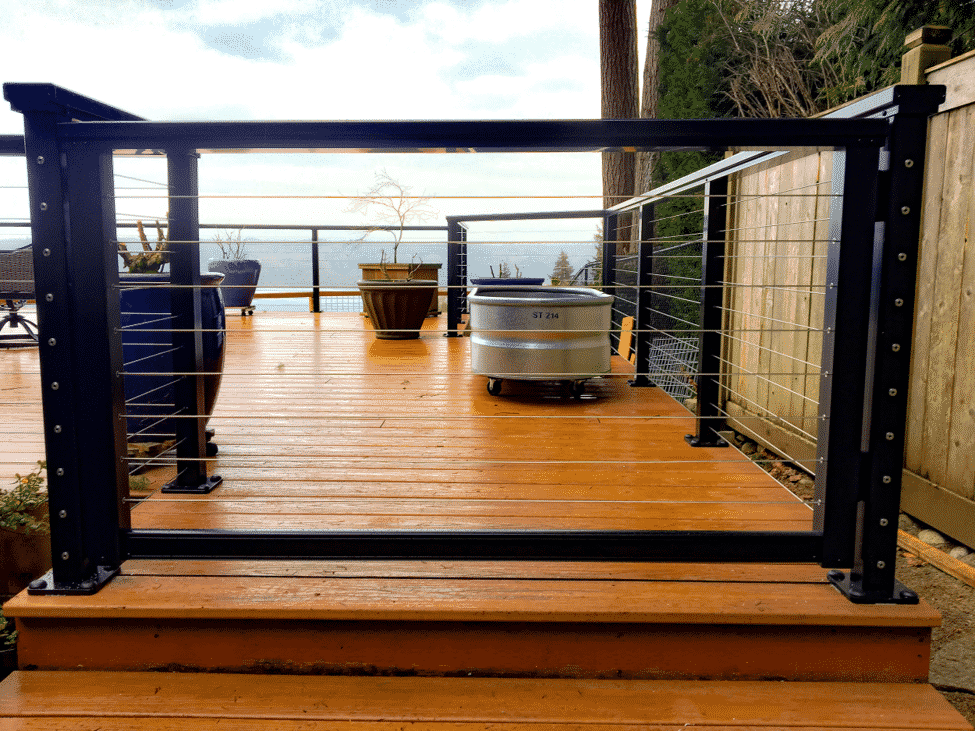

A cable railing system is a code-compliant railing that offers an aesthetic advantage with limited visual disruption compared to other railing options. All our cables are less than an inch in diameter and meet building codes following specific guidelines.

Code Considerations for Cable Railing. Which Code?

Municipalities, the state, and countries all issue building codes. When in doubt, choose the most conservative option. In many cases, the municipal code supersedes codes issued at higher levels.

For more information about handrail and guardrail codes, click here to view the International Residential Code.

A Note About Handrails and Guardrails

Building codes frequently have separate provisions and requirements for handrails versus guardrails.

A guardrail must be present on every cable railing system. Guardrails, as defined by the International Residential Code (IRC), are a “building component or system of building components located near the open sides of elevated walking surfaces that minimize the possibility of a fall from the walking surface to the lower level.” Guardrails are required for all elevated decks and are the primary way of keeping users safe.

Handrails are defined by the IRC as “a horizontal or sloping rail intended for grasping by hand for guidance and support.” Handrails are required for at least one side of runs with four or more steps.

In essence, guardrails prevent people from falling off a deck, while handrails help people move up and down stairs safely.

What Is Graspability?

A handrail must be high enough to stop someone from falling over and sturdy enough to support someone’s weight. It also needs sufficient graspability. Graspability refers to the specific shape requirement for someone to hold onto the handrail.

Many cable railing systems come with materials to build code-compliant handrails and guardrails. Some companies, such as RailFX, offer several rail designs that accommodate graspability requirements while providing a stylish look.

However, if you’re using your own materials, check the IRC and any local codes to ensure your guard and handrails are sufficiently graspable.

Sphere Rules

Sphere rules are fairly straightforward and apply to all railing systems. IRC sphere rules state that the spacing between railing components cannot allow a 4” sphere to pass through it. Stairs are an exception. They have a 6” sphere rule between the step treads and the bottom rail.

Cable railing doesn’t have the same rigidity of wood or steel balusters. Therefore, you can’t simply measure the space between cables. Install cables close enough together so even if they stretch, a 4” sphere still can’t pass through. Contractors often install cables with 3-3½” spacing.

Tensioning is another requirement for cable railing. Applied tension to the cable helps resist a 4″ sphere from passing through. It is a critical specification to ensure the safety of a cable railing system.

Other Safety Considerations

Tension

Tension is the critical component to meeting sphere rule requirements. It impacts the cable’s load-bearing capability if someone or something runs into it. Tension keeps the cable taut enough to comply with the sphere rules and is an important factor in the safety of the system.

Different materials have different stretch properties, and high tension cables can lose tension over time, which can negatively impact their code compliance. Stainless steel typically stretches less than aluminum, and the recommended cable configuration is a 1X19 cable—that is, 19 wires woven into one stronger cable structure—to maintain strength and flexibility.

Posts should be strong enough not bow under high tension. Choose the Invisiware Receiver® hardware by RailFX. It’s easy to create the correct amount of tension by using a simple Allen wrench to adjust tension as needed.

The Inivisiware Receiver, our mounting hardware, is strong enough to withstand all forces. A Professional Engineering Firm with stamps in 38 states officially reviewed The RailFX system and concluded our system meets all applicable code requirements.

Laddering

Often there is a loss of tension over time due to stress on the wires, relaxation and applied loads, such as kids trying to use it as a ladder. However, tension is easily adjusted with an Allen wrench using hardware such as our Invisiware receivers.

While horizontal cable infill is a perfectly acceptable and safe option, some still have apprehension using this system. In this case, vertical cable infill is a good alternative as it eliminates the ability for climbing on the infill. This option is inherently more expensive and slightly more visually disruptive due to the number of cables needed.

Which Cable Railing System Should You Choose?

RailFX offers a number of code-compliant railings, including RailFX cable railings. Engineered with stainless steel hardware, system railings are long-lasting without interrupting a homeowner’s view and many kits are easily re-tensioned using only an Allen wrench. For more information, visit our website.